Daniel Croft is an experienced continuous improvement manager with a Lean Six Sigma Black Belt and a Bachelor's degree in Business Management. With more than ten years of experience applying his skills across various industries, Daniel specializes in optimizing processes and improving efficiency. His approach combines practical experience with a deep understanding of business fundamentals to drive meaningful change.

Generate CitationCopy to Clipboard

Understanding the reliability of your measurement system is crucial for effective process management, especially in the context of Lean Six Sigma. Attribute Agreement Analysis (AAA) serves as an invaluable tool for this purpose.

This guide aims to provide a detailed insight into AAA, covering its definition, importance, and methodology. We’ll explore how to assess the reliability of attribute (categorical) data by measuring the agreement between multiple appraisers’ ratings against a known standard. By the end, you’ll be equipped to conduct your own AAA, ensuring the robustness of your data and enhancing your continuous improvement efforts.

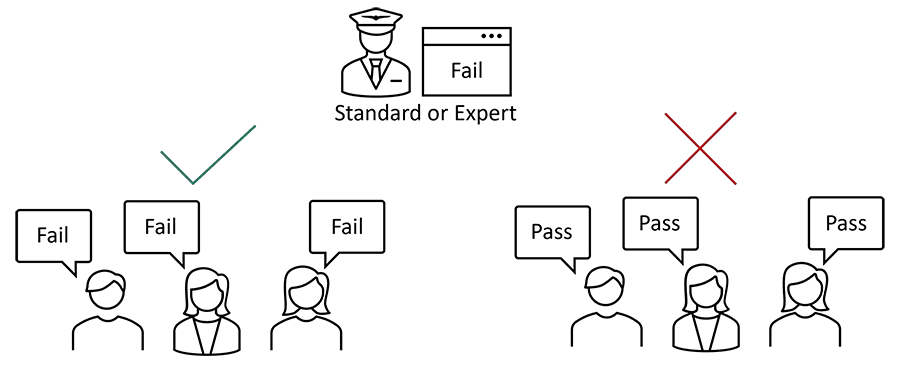

Attribute Agreement Analysis is a statistical technique used to evaluate the agreement among different appraisers’ judgments on categorical data. It assesses whether multiple individuals making judgments or assessments on the same item would reach a high level of agreement by evaluating the repeatability, reproducibility, and overall accuracy of the appraisers. Repeatability refers to the variation in assessments when repeated by the same appraiser, while reproducibility refers to variation when assessments are made by different appraisers on the same item.

AAA is pivotal for ensuring the quality and reliability of data in decision-making processes. It helps to:

Characterize the quality of data by identifying areas of non-agreement.

Calibrate appraisers, judges, or assessors for a higher level of agreement.

Enhance the consistency and accuracy of judgments, thereby contributing to better decision-making and operational efficiency. This technique finds applications across various sectors, especially in quality control, manufacturing, and any domain where accurate categorization and assessment are crucial for operational success.

In the context of Lean Six Sigma and continuous improvement, understanding different types of data is crucial for quality control and decision-making. Attribute data is a type of qualitative data that is categorized into labels or attributes, rather than numerical values. Attribute data is primarily divided into two types: Nominal and Ordinal.

Nominal data consists of categories that have no inherent or meaningful order. These categories are mutually exclusive and exhaustive, meaning that every observation can only belong to one category, and all possibilities are accounted for.

Examples in Continuous Improvement:

Graphical Representation:

In most cases, a bar chart or pie chart is used to represent nominal data. Each category gets its own bar or pie slice, and the height or size of the slice represents the frequency or percentage of observations in that category.

Ordinal data is similar to nominal data, but the categories have a meaningful order. However, the intervals between these ordered categories are not uniform or measurable.

Graphical Representation:

Ordinal data can also be represented using bar charts, but it is important to maintain the order of the categories. Sometimes, a line chart may also be useful to highlight trends across ordered categories.